As a separate sector, the B2B corporate promotional gift sector is constantly and rapidly developing in the face of the demand for new creative products every year. The expanding range constantly requires new printing opportunities, which generally leads to the development of the digital printing market and the creation of new printing technologies. You can get acquainted with the print technology for many promotional items on our YouTube page:

|

Digital printing 360 - Compared to round screens, it is possible to print full color, vivid images. UV ink technology does not emit volatile organic compounds (VOC) to the atmosphere. When combined with white underprint – possibilities are limitless on transparent objects.

|

|

Laser engraving 360 - Next level for inkless decoration, now possible on cylindrical products. Compared to conventional engraving, the engraving area is limited by the circumference of the cylindrical object. Can be used on mugs with handles. Best results on natural materials (metals, wood, bamboo, etc.).

|

|

Sublimasiya - Transfer kağızında xüsusi mürəkkəblərlə çap olunur, yüksək temperaturdan istifadə edilməklə materiala köçürülür. Çap şəkillərinin foto keyfiyyəti, həmçinin parlaq rənglər və kiçik detalların dəqiqliyi ilə tanınır. Ən yaxşı nəticələr və polyester material və ya polyester üzləmə üçün ağ fon tələb olunur.

|

|

Doming - Digitally printed full color label on self-adhesive polymer foil, covered by a thick layer of transparent epoxy resin, which both protects the image, as well as giving a premium, glossy look and finish.

|

|

Digital Label - A flexible way to brand various products in almost any shape, self-adhesive polymer foil will fit in positions not accessible by other print techniques.

|

|

Digital Printing UV (VOC free) - flatbed inkjet technology allows you to print vivid full color images on various materials – artificial and natural. Compared to Digital printing 360 – this technique requires flat, rigid products. White underprint extends possibilities on transparent materials.

|

|

Digital inlay - Xerographic full color print on paper is a perfect way to convey a message to Your customer. This technique is best for text and images, can be used for example: as a manual or “Thank You” notes or items where this is the only option available.

|

|

Button printing - Best way to stand out from the crowd with this full color button. Printed using xerographic technology on paper, assembled with glossy finish to give a premium look.

|

|

Digital Transfer - Technique of digitally printed image on carrier foil with heat activated glue, applied with high temperature and pressure. Advantage of this technique is full color. photographic quality of image and sharp details. Gives a premium look and feel, especially on textile materials.

|

|

Screen transfer - Conventional way of indirect printing using screen print. Can be applied on materials and places, where direct screen printing is not possible, in addition up to 8 different colors can be used on one image. Special colors available.

|

|

Ceramic transfer - Technique of printing image using special inks on paper, transferred to the item using water film and heated in extreme temperatures to assure durability. Special colors available. Recommended for ceramic materials.

|

|

Screen printing - Image exposed onto a screen mesh, through which ink is squeezed on to the marked surface. Main advantage of this technique is its large printing area on flat surfaces, on almost any material, along with the possibility to use special colors. First choice for textiles. Maximum of 4 colors in one image. Special colors available.

|

|

Pad printing - Image transferred to products surface from engraved cliché by silicone tampon. Most versatile indirect marking technique on almost any rigid shape and material. Maximum of 4 colors in one image. Special colors available. Cost efficient technique on small items.

|

|

Round screen printing - Evolution of screen printing which allows this print method on to cylindrical and conical products. Compared to pad printing, this technique allows for a much bigger printing area. Can be used on mugs with handles. Maximum of 1 color. Special colors available.

|

|

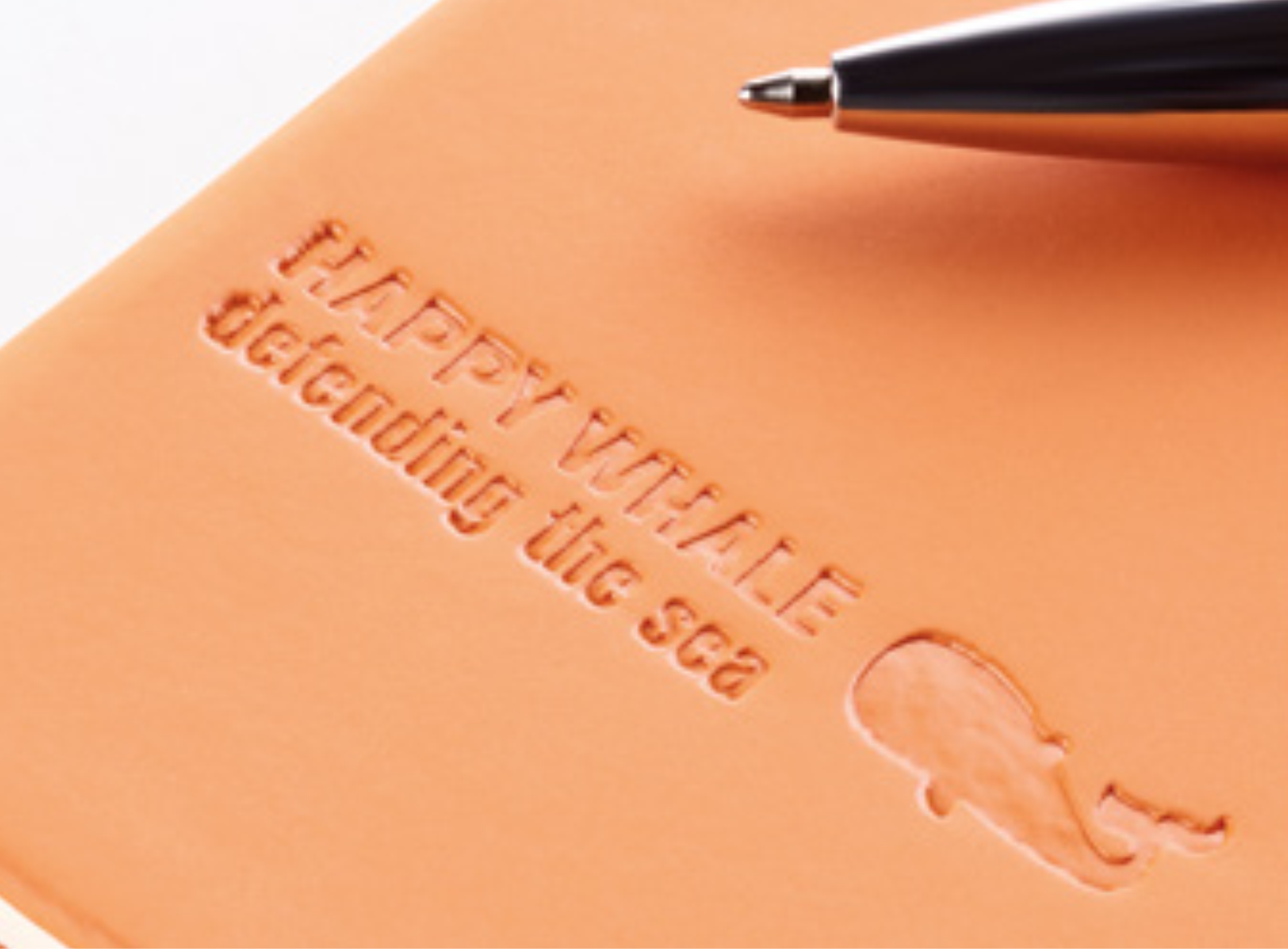

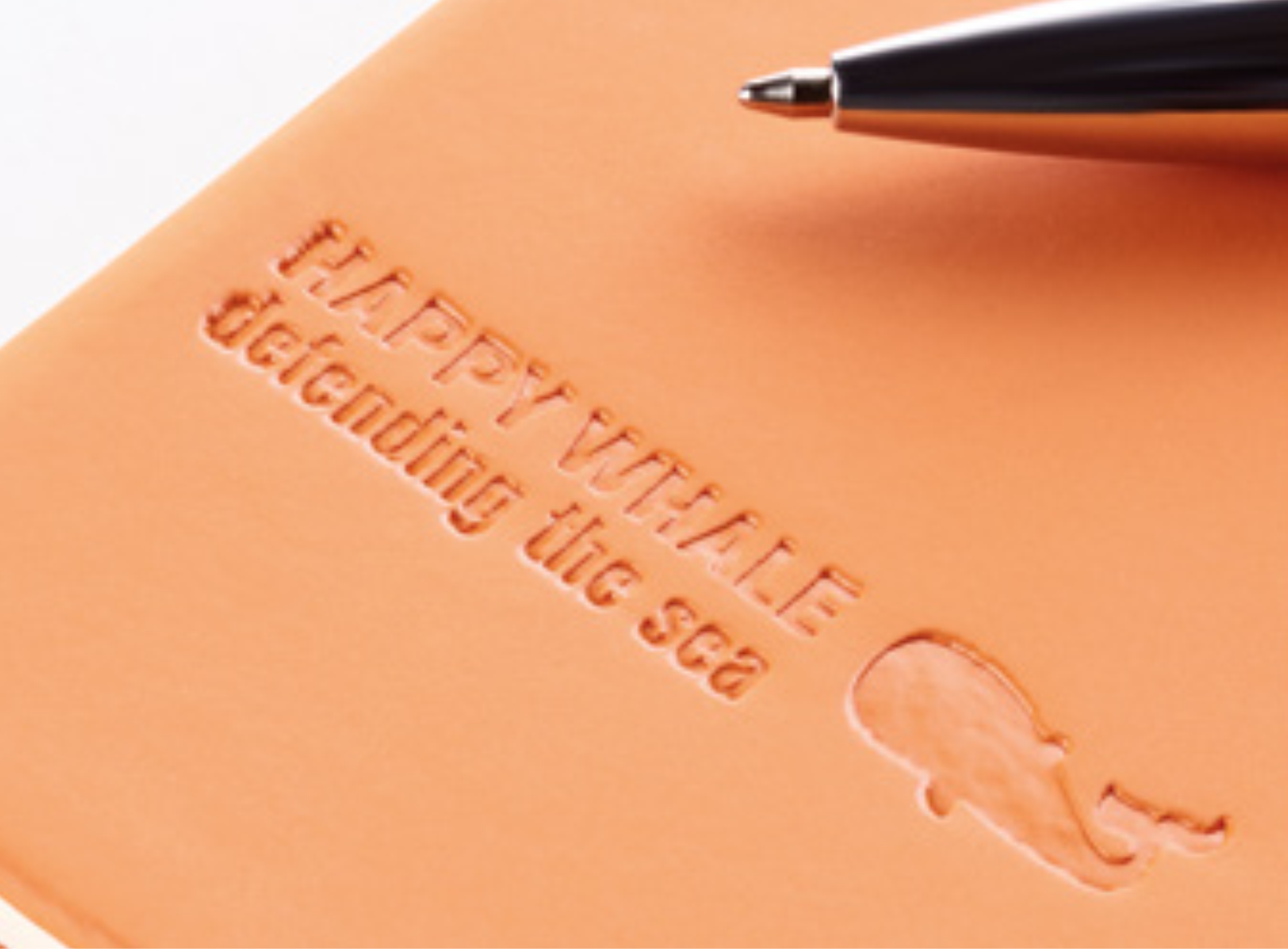

Debossing - The engraved metal stamp is heated and is pressed against the material creating a permanent depression in the shape of the customer’s artwork. Best results can be achieved on leather, PU, cardboard materials, like notebooks, organizers.

|

|

Embroidery - Computerized stitching allows complex artworks being sewn in the material, creating premium and permanent marking. Glossy effect. Maximum of 8 colors in one image. Possible on textile materials like bags, t-shirts, jackets, etc, as well as caps.

|

|

Laser engraving - Marking is permanent, by selectively removing microscopic layers of material, thus creating visible marks on the surface. Colour varies depending on processed material. Best results on natural materials (metals, wood, bamboo, etc.).

|